Description du produit:

Qu'est-ce que le matériau G10 FR4 ?

G-10/FR-4 is a composite material consists of a continuous woven glass cloth material with an electrical grade epoxy resin binder.As a thermoset material, This grade has outstanding mechanical and electric strength as well as good dielectric properties. G10/FR-4 is widely used in electrical and electronic applications.

Is FR4 the same as G10?

Both G10 and FR4 are composite materials which made of glass fiber cloth and epoxy resin.The difference between G10 and FR4 is that most of what is called G-10 is actually FR-4, the flame retardant version of G-10. NEMA grade G10 glass epoxy is natural in color and non-brominated / non- flame retardant.FR-4 can usually be used where G-10 is called out, however, G-10 should not be used where FR-4 is specified.

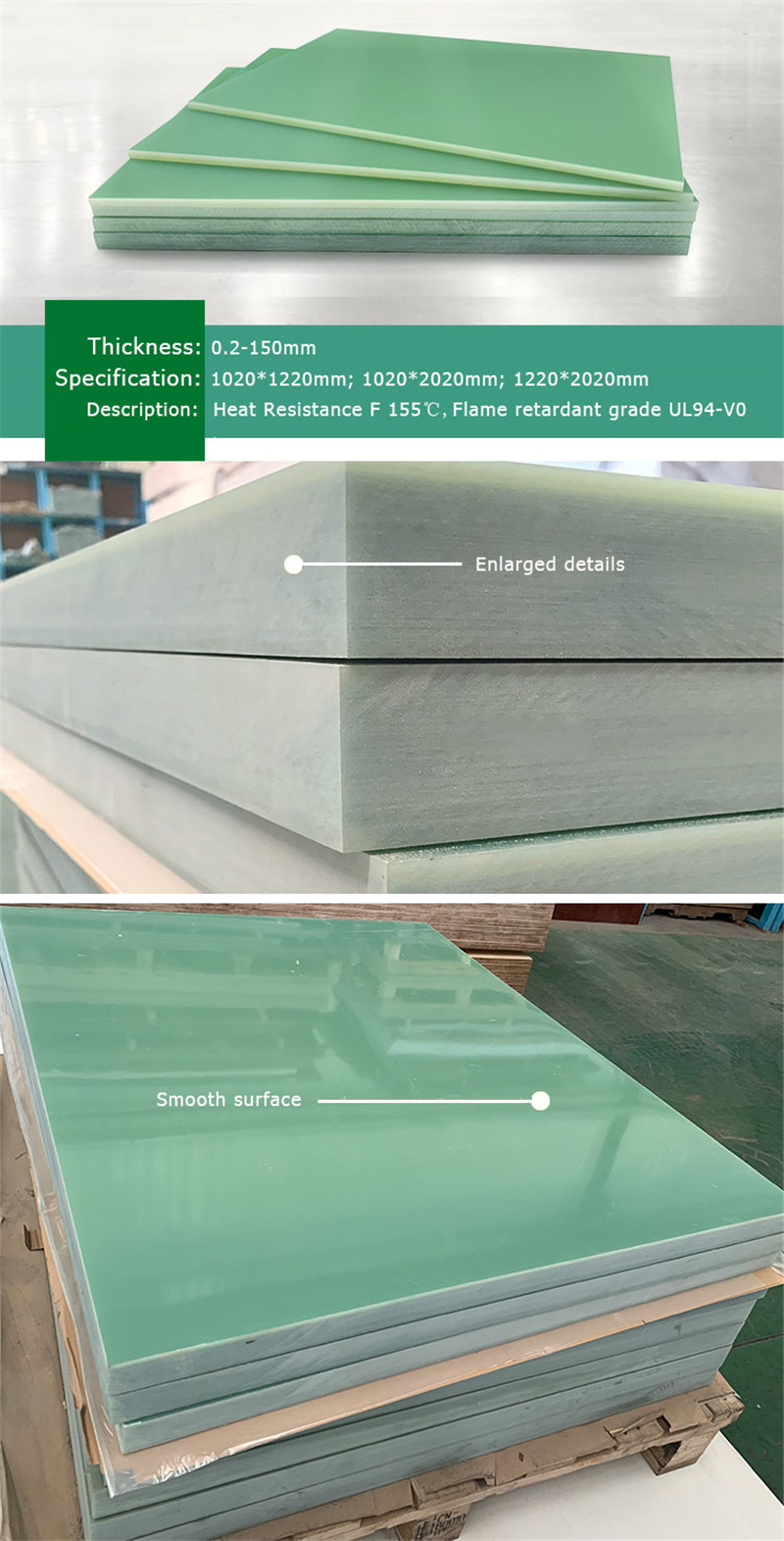

Standard Specifications of G10/FR-4

LXW:1220X2040mm

LXW:1220X1020mm

LXW:1220X2440mm

JY machinery offered G10/FR4 sheets on standard specification,but customized sizes are available.Contact usinfo@jycncmachining.com to get free samples of G10 sheet and FR4 sheet.

Fabrication

G-10 and FR-4 can be fabricated using standard machine tools.JY Machinery provides precision CNC machining and fabrication services,Working with G10/FR4, G11/FR5, GPO3 fiberglass, ABS, PPS and cotton/paper phenolic materials. Prototype and production volume are offered. Serves the electrical, electronics, aerospace, air force and military industries.

What models of G10/FR-4 products are produced by JY Machinery?

JY Machinery manufactures NEMA grade G-10/FR4 products. These materials can be made into tubes, rods and sheets. They can also be machined into gaskets, spacers and other components. We can also design a specific you based on your unique application. Whatever your manufacturing or assembly needs, JY Machinery can improve your product at a reasonable price. Our laminates,tubing, rods and spacers are designed with precision in mind.

Products Show

Data sheet of G10 FR4 Material

Standard |

GB/T 1303-2009 / IEC60893-2003 |

|||||||

Basic Information |

Chinese Name |

3240 |

||||||

IEC |

EPGC201 |

EPGC202 |

EPGC203 |

EPGC204 |

EPGC306 |

EPGC308 |

||

NEMA |

- |

FR4 |

G10 |

FR5 |

G11 |

- |

||

Basic Material |

Glass fiber cloth |

Electronic Grade Glass Fiber Cloth |

||||||

Resin |

Epoxy |

Heat-resistant Epoxy Resin |

||||||

Color |

Natural |

Natural/Green |

||||||

No. |

Test Item |

Unit |

Value |

|||||

1 |

Density |

g/m³ |

1.8~1.95 |

|||||

2 |

Vertical Layer Bending Strength (normal) |

MPa |

≥340 |

|||||

3 |

Résistance aux chocs de la couche parallèle (méthode du faisceau simplement pris en charge) |

KJ/m2 |

≥38 |

|||||

4 |

Résistance électrique de la couche verticale (huile de transformateur 90 ℃) (épaisseur 1 mm) |

Kv/mm |

≥14.2 |

|||||

5 |

Tension de claquage de couche parallèle (huile de transformateur 90 ℃) |

kv |

≥35 |

≥35 |

≥40 |

≥35 |

≥40 |

≥35 |

6 |

Constante diélectrique (50Hz) |

- |

≤5.5 |

|||||

sept |

Facteur de perte diélectrique (50Hz) |

- |

≤0.04 |

|||||

8 |

Résistance d'isolement après immersion |

Ω |

≥5.0*1010 |

|||||

9 |

Indice de suivi des preuves (PTI) |

- |

- |

- |

- |

- |

≥200 |

- |

dix |

Combustibilité |

- |

- |

V-0 |

- |

V-0 |

- |

- |

11 |

Indice de température |

- |

130 |

130 |

155 |

155 |

155 |

180 |

12 |

Absorption d'eau (épaisseur 1-20 mm) |

mg |

17 ~ 73 |

|||||

Remarque : les valeurs de plage sont mesurées pour différentes épaisseurs |

||||||||

Notre usine

Laissez-nous un message pour obtenir un devis et un échantillon!

Si vous êtes attiré par nos produits, veuillez nous envoyer un message et nous vous contacterons dès que nous le recevrons. Courriel : info@jycncmachining.com Whatsapp : +8615880913506